Products & Applications

Product Categories

○ Product Details

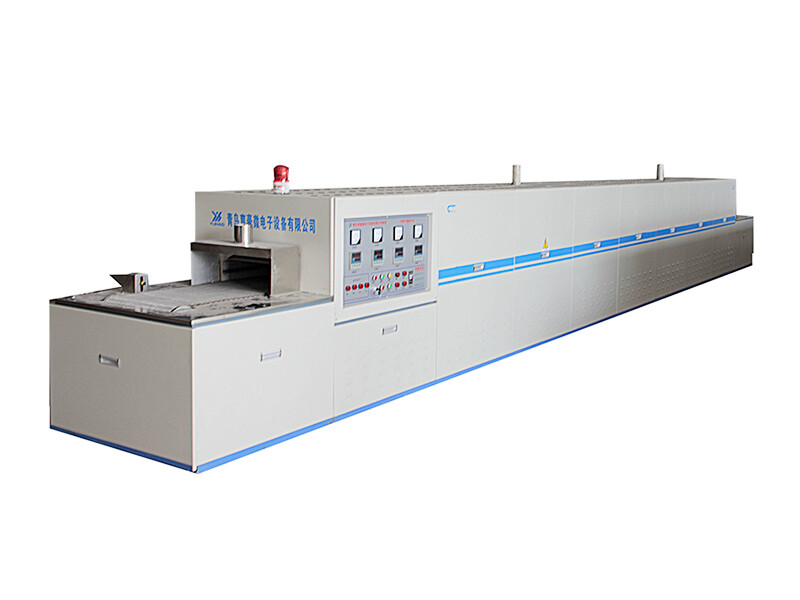

1. Product Application and Description:

Mainly used for various electronic components, diodes, rectifier bridges, automotive electronics and other products held by tweezers, combined with solder paste, solder strips and other related soldering materials in an atmosphere-protected soldering process.

The equipment mainly consists of heating system, gas system, cooling system, transmission system, electrical control system, frame and other components.

2. Technical Parameters:

3. Equipment Features:

The control part consists of an industrial computer, PLC, high-precision temperature controller and other components.

1) Independent control for each temperature zone, capable of controlling silicon modules and thermocouples to form furnace temperature control loops, precisely controlling furnace temperature (external temperature). It can also monitor and record the temperature in the working channel during preheating operations.

2) Temperature curve recording and analysis function: Regularly measure and analyze the actual temperature curves of the furnace chamber and workpiece surface; externally connect 1 long thermocouple to detect the furnace chamber temperature in real-time (preheating), displaying and storing the measured temperature curve.

3) The display screen shows the set temperature, measured temperature, and overtemperature alarm signals, equipped with an alarm light tower.

4) Historical data recording function: Stores 10 sets of fixed process parameter settings, process temperature curves, speed records, temperature records, and other alarm information.

5) Can connect to ERP/MES, remote monitoring, and equipment operation.

6) Uses a commercial computer for control, with a user-friendly human-machine interface display format, enabling curve storage and automatic recall, large-capacity storage. Customers can set multiple usage curves for different products and recall them anytime.

7) Automatic alarm when furnace temperature exceeds the set value or thermocouple breaks, cutting off the heating power supply.

8) Parameter adjustment: Including temperature, control parameters, and other adjustable parameters of the lower machine, all can be controlled on the display screen.

9) Added timed heating switch function + conveyor belt automatic switch + gas circuit automatic switch.

○ Company Profile

Qingdao Yuhao Microelectronics Equipment Co., Ltd. was established in 2008 as a high-tech enterprise integrating R&D, manufacturing, and sales. The company specializes in electric heating furnace equipment, heating furnace thermal fields, and graphite tool processing. Our products and services cater to various industries including electronic components, semiconductor materials, and solar photovoltaic sectors.

?

Yuhao is a national high-tech enterprise and a provincial specialized and innovative SME. We hold trademark registration rights and import/export operation licenses, having passed ISO9001 quality management system certification with over 45 patents.

○ Company Certifications

○ Online Consultation

○ Related Recommendations

Message Consultation